Short Path Distillation Plant for Base Oil

- Home

- Base Oil Plant

- Short Path Distillation Plant for Base Oil

Product Description

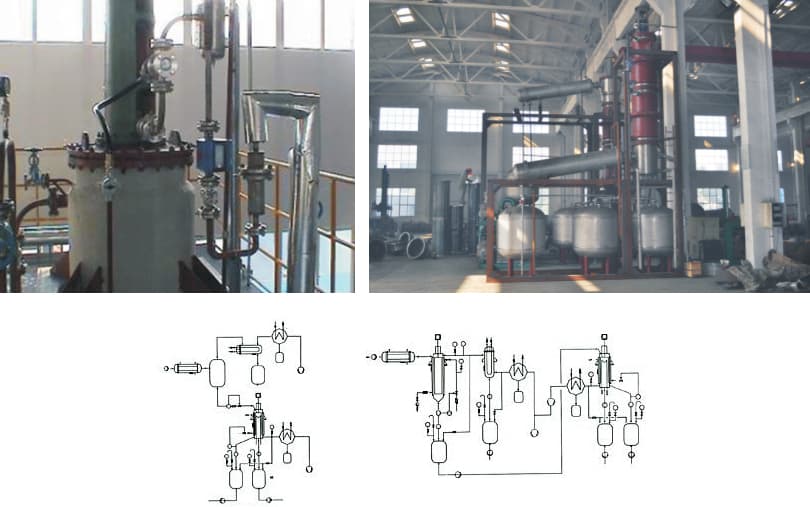

Short Path Distillation Plant for Base Oil

Short-path distillation (also called Molecular distillation ), is a distillation technique that involves the distillate travelling a short distance, often only a few centimeters, and is normally done at reduced pressure. It is a thin film evaporator(TFE). Many such as heavy petroleum residues, chemicals, medicines and natural foods, health products, fatty acids, etc., are often heat-sensitive, viscous and / or have high boiling point materials. To separate these materials from their other components and maintain the quality of the product, they can only be rectified at a low boiling temperature or less than the boiling temperature, and only in a short time, thermal decomposition Or polymerization is reduced to eliminate damage to the product.

VMETS short-path evaporator is suitable for this application. The condenser is built in the evaporator, directly opposite the heating distillation. VMETS has more than 20 years of research and development and practical experience in waste oil regeneration projects, with a group of professors from the petrochemical industry as a solid technical foundation, research and development and promotion of waste oil regeneration multi-stage short-path distillation process, suitable for different scale waste oil regeneration Processing volume of corporate customers. The lubricating base oils of different viscosity grades produced by this process equipment meet the quality standards of Groupe I and Groupe II base oil.

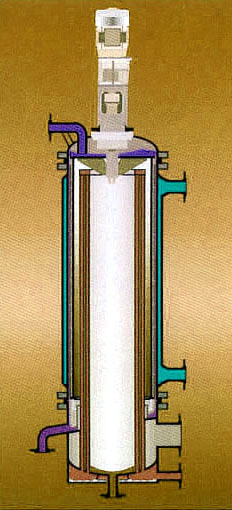

Wiped Film Evaporators consists of a vertical heating-medium-jacketed cylinder and the feed waste oil flows down as a film along the internal surface of large diameter jacket. Waste oil liquid is distributed on the tube wall by a rotating assembly of blades mounted on shaft placed coaxially with the inner tube. Compared traditional heating kettle distillation, the main advantage is that rotating blades permits handling of extremely viscous solutions, could produce higher viscosity base oil; and high efficient and evenly heating to avoid fouling. With internal condenser, the distillation path to condenser path is short which could reduce the pressure drop largely.

Features

- High heat flux

- Low residence time

- Low pressure drop allowing operation down to 1 mbar absolute

- Robust design minimizing maintenance costs

- No dead zones and no liquid hold-up

- Easy to clean

- Low fouling

- Suitable for high viscosity base oil production

- Suitable for evaporation of WMO with very high boiling points

Operation Process

VMETS short-path evaporator consists of a cylindrical body with jacket heating, internal condenser and rotor. The inner condenser is located in the center of the evaporator, and the rotor with the wiped film system rotates between the evaporator and the condenser.

The distillation process is: the material is added from the top of the evaporator, the material liquid distributor on the rotor is continuously and evenly distributed on the heating surface, and the film scraper scrapes the product into a very thin, turbulent liquid film. In this process, the light molecules that escaped from the heating surface condensed into liquid on the condenser almost without collision, and flowed down the condenser tube and discharged through the discharge tube at the bottom of the evaporator; the residual liquid is heavy The molecules are collected in a circular channel under the heating zone, and then flow out through the side discharge pipe.

Advantages

- ECO Friendly with full set of tail gas adsoprtion system and deodorization system

- Non Acid used in whole process

- High recovery rate The recovery rate of lubricating oil exceeds 95% of the lubricating oil fraction in the used lube oil

- Genuine distillation with Wiped film evaporator and Short path distillation to produce much purer light base oil, medium base oil and heavy base oil

- Stable PLC control for automation with Germany CPU Modules

- Transnational remote update and maintenance

- Easy operation

- Conversion of LGO & Residual Portion as salable Furnace Oil

- Continuous distillation to save energy