Lubricating Oil Blending Plant

- Home

- Base Oil Plant

- Lubricating Oil Blending Plant

Lube oil Blending and Filling Plant

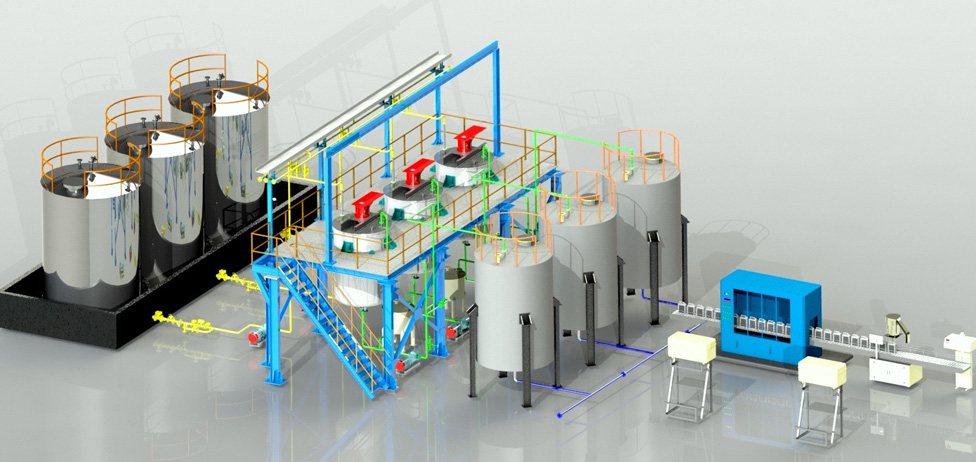

A typical blending plant comprsies of the following sections :

- Tank farm

- Blending area

- Storage, Filling And Packing

Base oils from the tank farm are pumped into the blending vessels and mixed with additives at the required temprreature to obtain a homgeous mix.there are several methods to achieve and optimum blend depending on the product and plant requirments. The blended product is then filtered and transferred to storage tanks from where it is taken to the filling station and packed in containers or barreles.the entire process can be carried out in a basic manually operated plant or auotmated plc controled plants.

The lube oils are manufactured to api or other required specifications

Various lubricating base oils are charged into blending vessel through flow indicator cum controller in fixed proportions depending on finished product desired. This is then dehydrated at atmospheric pressure followed by addition of various additives. Subsequently the blended product is filtered through centrifugal filter which retains any particle of size above 2 micron. This may then be filled in packs varying from ½ lit to 210 lit.

Material Balance / Yields

Since the process involved is that of mixing hence losses are minimal, yields being about 99%.

Vmets’s Lube oil blending project is favourable to manufacture below lubes oil –

- Different Grade of Engine oil

- Transmission / Gear oil

- Break oil

- Hydraulic oil

- Industrial oil

- Transformer oil

- White oil

VMETS offers complete turnkey plants on epc basis for the production of a wide range of lubricants oil. The services offered by us includes plant design. detailed engineering services, tank farm design, equipment manufacture and supply, erection and commissioning. lab set up. training formulations. raw material sourcing, supply and marketing help across mena & globally.

Applications to extract the base lube oil from below source:

1.Used waste lube Oil Plant

2.Virgin crude Oil Plant

3.Oil blending Equipment to Make a perfect grade.

4.Final Filling and labelling Machine

Equipments & Utilities under scope of VMETS for LOB Plant –

Thermic Fluid Heater Air compressor cooling tower, Blending vessel with heating coil/jacket duly insulated, Dissolution vessel similar to above for making polymer solution, Charging pump with motor provided with suction stainer, Circulation pump with motor provided with suction strainer, Barrel filling arrangement with conveyor, Automatic /semi automatic filling machine for filling drum’s / tins, Basket / bag type filter with heating jacket, Screw pump with motor for charging polymer solution.