Base Oil Solvent Extraction Refining Plant

- Home

- Base Oil Plant

- Base Oil Solvent Extraction Refining Plant

Extraction Process

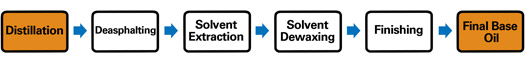

The following is a simplified description of the VMETS extraction process:

Deasphalting

Propane deasphalting takes the residuum from the very bottom of the column (the heaviest, largest molecules) and separates them into two products: tar and compounds that are similar to the lube distillates but have a higher boiling point. This material is called deasphalted oil, and it will be refined in the same manner as the lube distillates.

Solvent Extraction

Solvent Extraction

Solvent extraction is the term used for the removal of most of the aromatics and undesirable constituents of oil distillates by liquid extraction. Commonly used solvents contain phenol, furfural and sulphur dioxide. The resulting base stocks are raffinates (referred to as neutral oils) and an extract that is rich in aromatic content, which is highly sought after as a process oil or fuel oil.

Dewaxing

After solvent extraction, the raffinates are dewaxed to improve low-temperature fluidity. This process again produces two products: a byproduct wax that is almost completely paraffinic and a dewaxed oil that contains paraffins, naphthenes and some aromatics. This dewaxed oil becomes the base stock for many lubricants, but there is one more process that can be done to make a premium product.

Mineral Base Oils

The base oil is the foundation of a finished lubricant. A finished lubricant is one that is ready for use and is a blend of both base oil(s) and additives. Remember, the additives formulated into the mineral base oil will alter the properties of the base oil.

The basic function of a refinery is to separate the crude oil into its useful components and remove the components of unwanted materials. Base oils or base stocks, as they are sometimes called, are created from separating and cleaning up crude oil. They are one of several liquid components that are created from crude oil.

Gasoline is the lightest or smallest hydrocarbon component, followed by kerosene or jet fuel, diesel fuel, base oils, waxes and asphalt or bitumen, which is the heaviest, thickest material. Base oils are prepared from crude oils through the use of the following series of processes which, to some degree, must be applied to all crude oils for refining and also re-refining processes.

Solvent Extraction

Solvent Extraction is the term for the removal of most of the ring structures and aromatics (weak, undesirable components) of oil distillates by liquid extraction. Common and suitable solvents are phenol, furfural and sulphur dioxide. Furfural is used extensively as the extractant for the refining of paraffinic oils. This results in base stocks that are neutral oils and an extract fluid that is rich in aromatic content, which is used for process oils and fuel oils.

After solvent extraction, the resulting materials are de-waxed to improve low-temperature fluidity and then sometimes hydrofinished with hydrogen gas to further improve the color and stability.

The final quality of the base oil is determined by the severity of the application of temperatures and pressures in the hydrofinishing process. The base oils are now ready to be selectively blended with the appropriate additives to achieve the desired physical, chemical and performance properties of the finished oil.

SOLVENT EXTRACTION TECHNOLOGY FOR UPGRADING BASE LUBE DISTILLATES

Adapted from crude oil refining technology for the used oil recovery sector, VMETS offers Solvent Extraction to upgrade recovered base lube distillates(or VGO) to base lube oils having Group I / Group II properties.

VMETS’ Solvent Extraction Process effectively improves typical recovered oil by:

- increasing the saturates by 3 – 5+%,

- decreasing Sulfur content levels below 50ppm

- dramatically improving oil color from ASTM 4.0 – 7.0 (medium to dark amber), down to ASTM less than 1.0 – 1.5 (pale to light gold)

- significantly enhancing base oil stability (no color deterioration or gum formation in storage)

- effectively dropping PAH content to BDL (below detectable levels)

- markedly reducing odor

solvent extraction plant